Specialized Horst Pivot Bearing Tool (Kenevo, Levo, Stumpjumper, Status 2021/2022/2023 onwards)

Regular price £16.50

Horst Pivot Tool (Kenevo, Levo, Stumpjumper, 2021/2022 onwards)

*** Buy one, get one 30% off any mix of pullers and presses (applies to individual tools only, not kits) ***

Note that this tool only addresses the horst pivot bearings (the pivot beside the dropout). Our regular puller and press kits are still required for the other pivots.

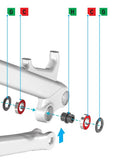

In 2021 Specialized started introducing a new design for the horst pivot (the rear suspension pivot next to the rear dropout). The new design includes a small axle that sits between, and extends through, the two bearings that make each pivot. Because this protruding axle blocks access to the inside of the bearing, conventional bearing pullers and press drifts can't be used on this pivot.

To address this problem, we've created a special version of our wind-out bearing puller. This version has been developed specifically for Specialized's new horst pivot axle. It uses a 6mm bolt to match the bore of the axle. Our tool can be used both to remove the old bearings and to press in the new ones.

The axle is marked 'H' in the image below:

Compatibility

We understand that the following model years use this horst pivot arrangement:

- Kenevo SL 2022 onwards

- Levo (Gen3) 2022-2024

- Levo (Gen4) 2025 onwards

- Levo SL Carbon 2023 onwards

- Levo SL Alloy 2023 onwards

- Status 2 140/170 2024 onwards

- Stumpjumper Alloy 2021-2023

- Stumpjumper 15 2024 onwards

- Stumpjumper EVO Carbon 2021 onwards

- Stumpjumper EVO Alloy 2022 onwards

This tool is only for Specialized bikes with this type of axle in the horst pivot. If you're bike doesn't have this axle extending through the bearing then our normal Specialized puller and press kits can be used instead.

How To

This bearing puller tool is simple to use. As well as the puller you will need a 10mm spanner and a 5mm allen key.

To remove a bearing:

- Assemble the bolt through the small drift, with the head of the bolt inside the countersink in the large end of the drift.

- Next install the bolt and drift through the horst axle in the frame, so that the smaller end of the drift is against the horst axle.

- Install the tool's receiving cup on the bolt where it protrudes through the other side of the pivot and add the washer and nut.

- Tightening the nut will push the axle towards the receiving cup, taking one bearing with it.

- It shouldn't require a lot of force. If in doubt, back off and check everything is installed as it should be.

- To remove the second bearing, first place the axle back in the remaining bearing, then repeat the process but with the tool installed on the other side.

To install the new bearing:

- Assemble the bolt through the small drift, this time with the head of the bolt against the small end of the drift, so that the drift's larger counter-sunk face can face towards the bearing.

- Next place a bearing against the drift, followed by the horst axle. The large diameter of the drift should be against the bearing, with the axle fitted against the bearing, fitting through the bearing and into the drift's countersink. It is necessary to include the axle to centre the bearing on the drift.

- Hold the bearing up against it's position in the frame and then install the receiving cup on the other side, followed by the washer and nut.

- Tightening the nut should press the bearing into the frame. There shouldn't be a a lot of resistance. Stop when you feel the resistance rise, indicating that the bearing has reached the bottom of the bore.

- Repeat the above step to install the second bearing.

If you have any questions please get in touch, info@bearingprotools.com, and we'll try to reply within one working day.

Note that each tool is specific to one bearing size. It is designed to match the internal and external diameters of the bearing and shouldn't be used on bearings of different size.

Bearing Presses and Blind Bearing Pullers

We offer a comprehensive range of 'expanding type' blind bearing pullers, bearing presses, bottom bracket, hub and headset tools. We offer 30% off every second item bought from our single tools menus, including mixes of pullers and presses.

Our tools can be selected either by the bearing's dimensions or by the bearing's standard reference code.

Standard references take the form of a three to five digit number, such as 688, or 6902 for example. These codes are often provided in the bike's user manuals, or moulded onto the bearing's seal. You might see something like 6902-2RS on the seal. The first digits are the standard reference. The second part (2RS in this case) refers to the seal type and doesn't matter for tool selection.

While the letter & numbers after the baring ref usually refer to the type of seal, you should keep an eye out for the suffix 'E', for example 698-E. This denotes that the inner race of the bearing is extended, which will affect puller and press selection.

Alternatively, tools can be selected by their inside (ID) and outside (OD) diameters and width (W).

Note that each tool is specific to one bearing size and can’t be used on bearings with different dimensions.

If you need any help then please feel free to email us! We usually reply within 1 working day.

You might also like

Fantastic tool, I replaced my bearings really easily using this tool, really well made, highlyrecommended 👍

Brilliant